Device remote access

Standardized data collection

Heating Balance Scheduling

Equipment remote maintenance

Device remote control

Data report analysis

Home

Product

Solution

About Us

Service Support

Link Us

Device remote access

Standardized data collection

Heating Balance Scheduling

Equipment remote maintenance

Device remote control

Data report analysis

Switch

需求背景

解決方案

Internet of Everything

Intelligent Collection

Edge Computing

Cloud Application

方案拓撲

方案效益

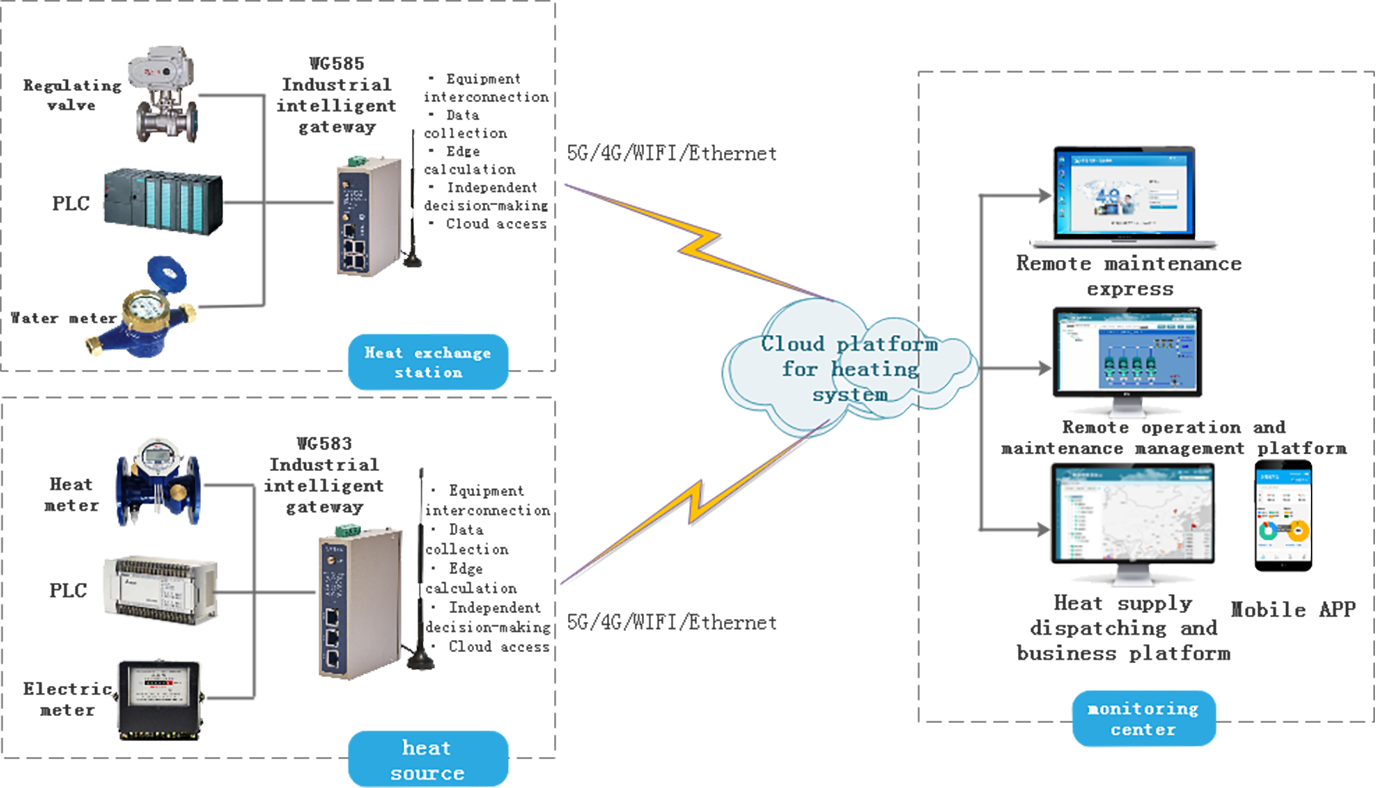

Connect heat sources, heat networks, heat exchange stations and industrial equipment distributed across the country to the cloud platform

Realize standardized data collection and upload to big data cloud platform

Through edge computing + cloud computing, the large-scale network balance adjustment and scheduling of the heating system is realized

Through the equipment express line, remote operation and maintenance management, remote debugging and remote maintenance are carried out for equipment across the country to improve the operation and maintenance efficiency and ensure the stability of the system.

Variable back control to realize remote control of control structure such as control valve

Integrate and analyze data from multiple dimensions to achieve business goals of cost reduction, energy saving, and optimization

應用案例

Realize the data visualization of factory

equipment network operation management and production line monitoring

and data interconnection of various information systems

Classic customers::

三一重工、京東方、富士康、寧德時代、愛仕達……

Realize data acquisition, remote control and maintenance of on-site equipment

Realize the monitoring of real-time data, historical data and alarm data

Realize operation management of field equipment and visual monitoring of production line data

Application industry projects:

rural sewage monitoring, urban sewage monitoring, secondary water supply monitoring……

Build a safe and reliable maintenance channel

Realize remote operation and maintenance of equipment distributed around the world

Reduce operating costs and improve service quality

Application industry:

water treatment equipment, construction machinery equipment, industrial lubrication equipment……

相關產品